Magnetic Levitation Blower Parts for Cooling Flow

Description

Basic Info.

| Model NO. | BOYUANG CASTING |

| Test of Surface Defect | Fpt |

| Elongation of High Temperature | Above 3% |

| Persistent Creep Temperature at High Tem | Above 975 Degree |

| Tensile Strength of High Temperature | Above 830MPa |

| Tensile Test Temperature | Above 900 Degree |

| Transport Package | Plywood |

| Specification | OEM and Customized |

| Trademark | OEM |

| Origin | China |

| HS Code | 8412901090 |

| Production Capacity | 50000PCS/Year |

Product Description

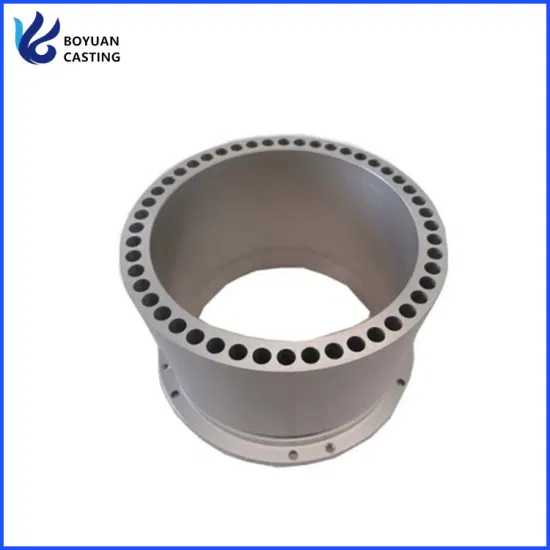

Magnetic Levitation Blower Parts for Cooling Flow

Product Display

Magnetic levitation blower cooling flow belongs to Magnetic levitation components, the machining process is three axis machining center, the material of blower cooling flow is aluminum alloy 6061, the machining surface smoothness of blower cooling flow can up to Ra0.8μm.

Our main products: Magnetic levitation blower cooling flow, Magnetic evitation blower impeller, Magnetic levitation blower compressor housing...

Our main machining process includes: five axis cnc machining, three axis cnc machining, cnc lathe...

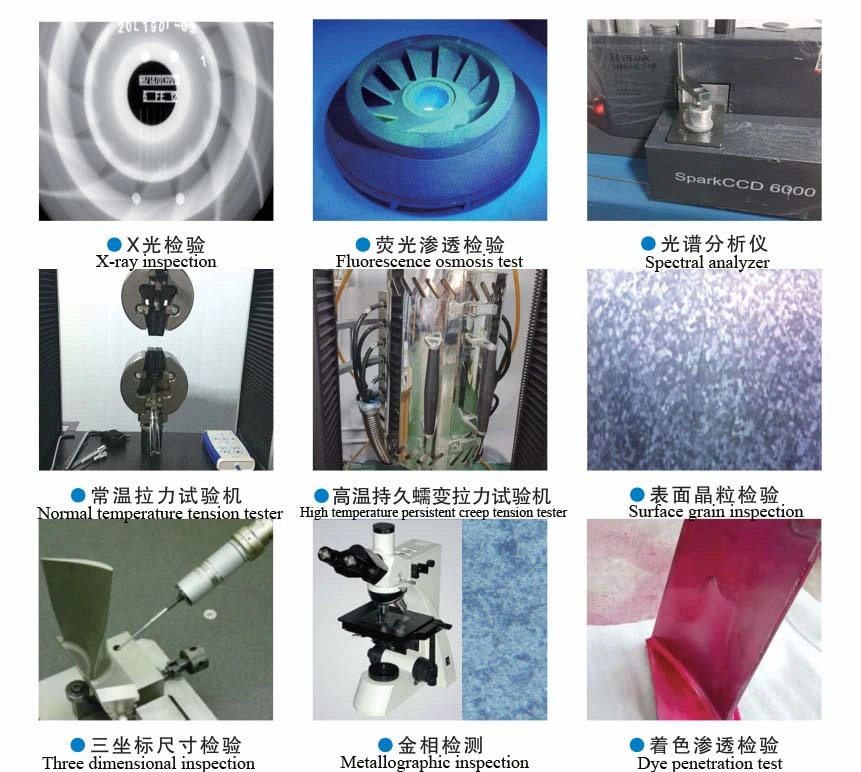

All inspection process will be finished in our factory, including non-destructive inspection and destructive inspection

Non-destructiove inspection:Visual inspection Surface defect testing Dye penetrant testing Radiography testing Ultrasonic testing Size testing by CMM

Destructiveinspection:Tensile strength testing Yield strength testing Hardness testing Chemical composition testing by spectrograph

We main offer OEM service, accoridng to customer's drawings or samples we can custom-made parts, if have any requirements please contact me.

| NON-Destructive Inspection | Destructive Inspection |

| 1.Visual Inspection | 1.Tensile Strength Test |

| 2.Surface Defect testing | Room Temperature Tensile Testing Machine |

| Dye Penetrant Testing | 2.Hardness Testing |

| 3.Inside Defecting Testing | Rockwell Hardness Tester |

| Radiography Testing | 3.Chemical Composition |

| Ultrasonic Testing | Spectorgraph |

| 4.Size Testing | 4. Casting Surface Grain Size Testing |

| CMM | Metallography Testing |

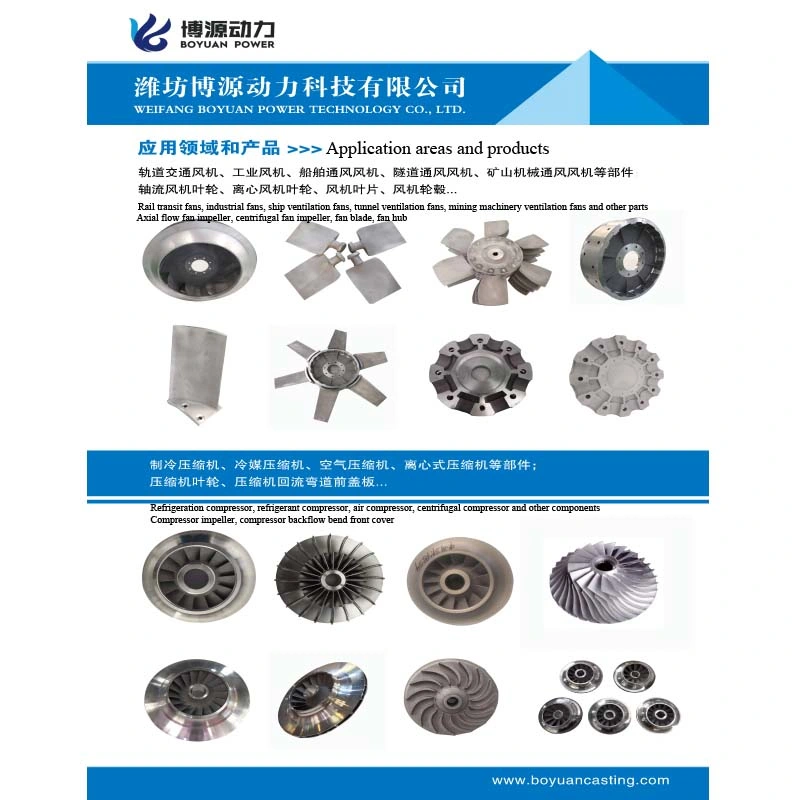

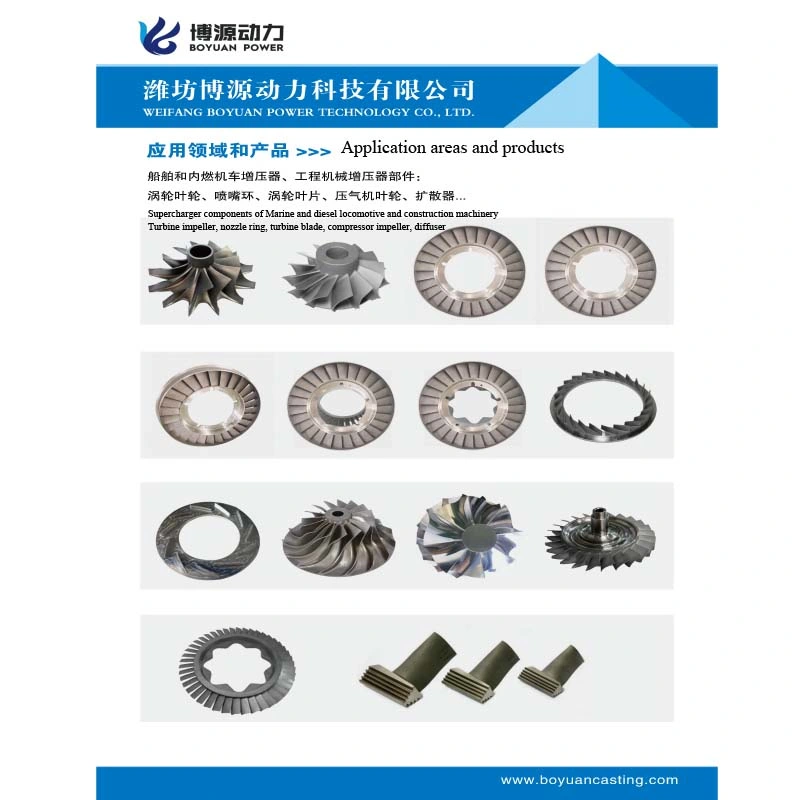

Weifang Boyuan Power Technology Co., Ltd. Specializes in the production of Aluminum Alloy impeller products and High temperature alloy impeller products, stainless steel impeller products. The company has a professional team that has long been engaged in the casting, processing and testing of impellers. Products are widely used in turbochargers, aero engines, industrial fans, compressors, blowers, rail transit, heavy mining machinery industry, refrigeration industry, marine engineering industry. The company has professional production line of Aluminum Alloy low pressure casting and high temperature alloy casting, stainless steel casting equipped with advanced inspection instrument.

1.What materials do you cast and machining?

We can cast and machining aluminum alloy parts and high temperature alloy parts.

2. How can I get the quotation?

Please send us information for quote: drawing, material, weight, quantity and request.

3.If we don't have drawing, can you make drawing for me?

Yes, we make the drawing of your sample and duplicate the sample.

4.When can I get the sample?

Sample: 25-30 days after you start to make mold. The accurate time depends on your product.

5.What is your main order time?

Order time: 30-40 days after the payment. The accurate time depends on your product.

6. What is your payment method?

Tooling: 100% TT advanced.

Batch order: 50% deposit, balance 50% to be paid before shipment.

7. Which kind of file format you can read?

PDF, ISGS, DWG, STEP, STP,X-T...

Welcome to contact with us if your are interested in any of our products!

Prev: Cheap Price 99.95% High Purity Mo1 Mo2 Mo3 Mla Tzm Pure (Mo) Molybdenum Metal Foil / Sheet 0.02mm

Next: Factory Price 0.1mm 0.05mm 0.02mm Gr1 Gr2 Gr3 Gr Gr7 Gr12 Pure Titanium Strip Foil Tape

Our Contact